Description

High-precision cylindrical roller bearings produced in single row and double row designs by SLF are ideal floating bearings. They are used not only as floating bearings, but also in applications demanding radially rigid, highly precise solutions with high load carrying capacity.

For exact radial clearance adjustment, in the standard version, the bearings are machined with a tapered hole (taper 1:12). Axial sliding on the shaft’s tapered seat face means that the desired radial clearance or radial preload can be adjusted.

These cylindrical roller bearings are also produced with a cylindrical hole. In this case, in the order designation, the “K“ (e.g. N1013M1.HP) is not used.

Dimensions/standards

In high-precision cylindrical roller bearings, the main dimensions are standardized according to ISO 15 (Radial bearings – boundary dimensions) or DIN 616 (Roller bearings – boundary dimensions).

Tolerances

Their intended use required that SLF high-precision cylindrical roller bearings have high accuracy and so they are normally produced in the HP tolerance class. This accuracy level corresponds to the SP tolerance class according to DIN 5412-4.

For applications with even more stringent requirements, we can produce bearings in the UP tolerance class according to DIN 5412-4.

The bearings can also be delivered with other tolerances upon request.

Bearing design types

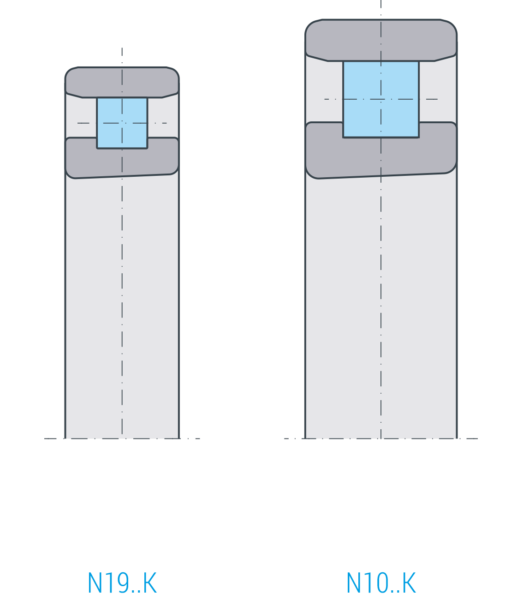

SLF produces single row high-precision cylindrical roller bearings in the N19 and N10 series. In the N design type, the inner ring has two shoulders, whereas the outer ring has none.

Clearance

High-precision cylindrical roller bearings have a standard radial clearance C1 that is smaller than the standard clearance CN. For this reason, the bearings are not interchangeable, meaning that the outer rings between the bearings cannot be exchanged, as is possible for the single row cylindrical roller bearings. Neither C1 nor NA (standing for German: not exchangeable) will be included in the description.

Other radial clearance design types are available upon request.

Table clearance for cylindrical roller bearings:

Cage

High-precision cylindrical roller bearings normally have a roller-guided solid brass cage. In single row high-precision cylindrical roller bearings, PEEK cages can be used upon request.

Working temperature

SLF’s high-precision cylindrical roller bearings with an outer diameter up to 120 mm are standard stabilized in dimensions by S0, meaning that they are subjected to heat treatment that makes them usable up to a working temperature of 150 °C. At more than 120 mm outer diameter, the cylindrical roller bearings are standard stabilized in dimensions by S1, meaning that they are subjected to heat treatment that makes them usable at working temperatures up to 200 °C. As a rule, however, the maximum working temperature is not limited by the bearing rings’ and rollers’ dimensional stability. Frequently the limitation is the cage or the lubricant. If you are uncertain or have specific questions regarding the maximum temperatures our bearings withstand, don’t hesitate to contact the SLF team.

Greasing/lubrication & sealing

High-precision cylindrical roller bearings are manufactured without seals. Consequently, the bearing location must be sealed around/ on the surrounding components. The sealing must ensure that no moisture and/ or contaminants can enter the bearing and that no lubricant is lost.

High-precision cylindrical roller bearings are delivered ungreased but must be lubricated with oil or grease. Choose the lubricant according to the application.

Dimensioning

Dynamic equivalent load

If bearings are subjected to radial and axial load simultaneously, these loads should be added together to provide an equivalent load to calculate the bearing lifetime. High-precision cylindrical roller bearings are characterized by a sole radial load.

| Pr | dynamic equivalent load [kN] |

| Fr | radial dynamic load [kN] |

Nominal lifetime

The bearing lifetime is defined as the number of revolutions or hours before damages to the bearing initially appears. Common reasons for breakdown are wear, jamming, overheating due to overload (mechanical or thermal), and material fatigue. The most frequent reason for failure in the case of high-speed applications is overheating with subsequent jamming of the bearing. Nominal lifetime of cylindrical roller bearings is calculated according to DIN ISO 281 as follows:

| $$L_{10} = (\frac{C_r}{P_r})^{10/3}$$

$$L_{10h} = \frac{L_{10} * 10^6}{60 * n}$$ |

| L10 | nominal lifetime in million revolutions, with 10% failure probability |

| L10h | nominal lifetime in hours, with 10% failure probability |

| Cr | dynamic radial load rating [kN] |

| Pr | dynamic equivalent load [kN] |

| Fr | radiale dynamische Belastung [kN] |

| n | speed [min-1] |

Static equivalent load

| P0 | static equivalent load [kN] |

| F0r | maximum radial static load [kN] |

Static load safety factor

For statically loaded high-precision cylindrical roller bearings, always inspect static load safety factor S0 in addition to nominal lifetime L (L10h).

| S0 | static load safety factor [-] |

| C0 | static load rating [kN] |

| P0 | static equivalent load [kN] |

Required minimal load

To avoid slippage between elements in contact, the cylindrical roller bearings must be sufficiently loaded. A minimal radial load in the order of magnitude of

has been shown to be necessary.

In most cases, the radial load from the weight of the components run on bearings combined with the external forces alone is higher than the minimal load required. Should this value not be met, contact an SLF application technician.