Customized

SLF is your partner of choice

for special requirements

Workpiece machining technologies are constantly evolving, and the requirements for machines are becoming more and more complex. As a result, spindle units must fulfill many individual criteria.

SLF specializes in the manufacture of customized spindle solutions from a single unit up. Your need for the highest levels of precision and accuracy is our goal and challenge – down to the μ!

Our service for your individual requirements begins with the planning phase. The spindle specialists in our design department support you in selecting appropriate spindle systems and additional components, such as tools, motors, sensors, cooling, lubrication, connections, etc.

The customized and individually made SLF

spindle systems will impress you:

Good value for money

Rapid project execution

Short design and lead times

Design and manufacturing from a single unit up

Service quality

In the spindle unit sector, SLF provides a wide range of solutions, from which we design and manufacture products that are exactly tailored to your needs, starting with one-of-a-kind units.

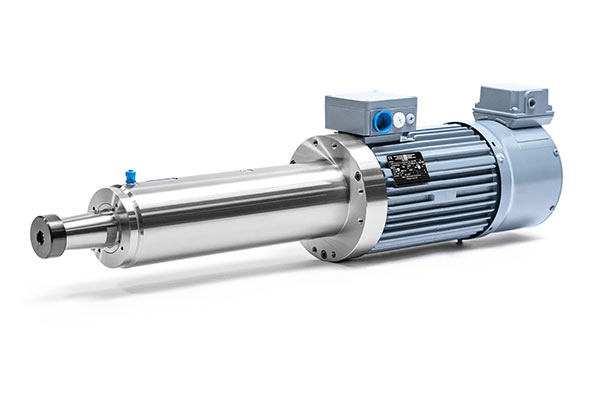

These include grinding spindles, workpiece spindles and tailstock sleeves, drilling and milling spindles, dressing spindles, as well as balancing and test spindles. We also offer solutions for special technologies, such as friction welding (press welding method to join parts by friction) or welding of rails for railway lines.

Our decades of expertise in a wide range of SLF spindle bearings, combined with an experienced team of designing engineers and skilled technicians and specially customized machinery, allows us to produce powerful and robust spindles for your individual machining tasks.

Our spindle manufacturing team excels in the swift, high-quality fulfillment of your project. We not only reply to your requests immediately and create offers and cost estimates promptly, but also produce from one–of-a-kind items up with short engineering and lead times.