Reliability under extremely demanding conditions

Roller bearings with outstanding durability

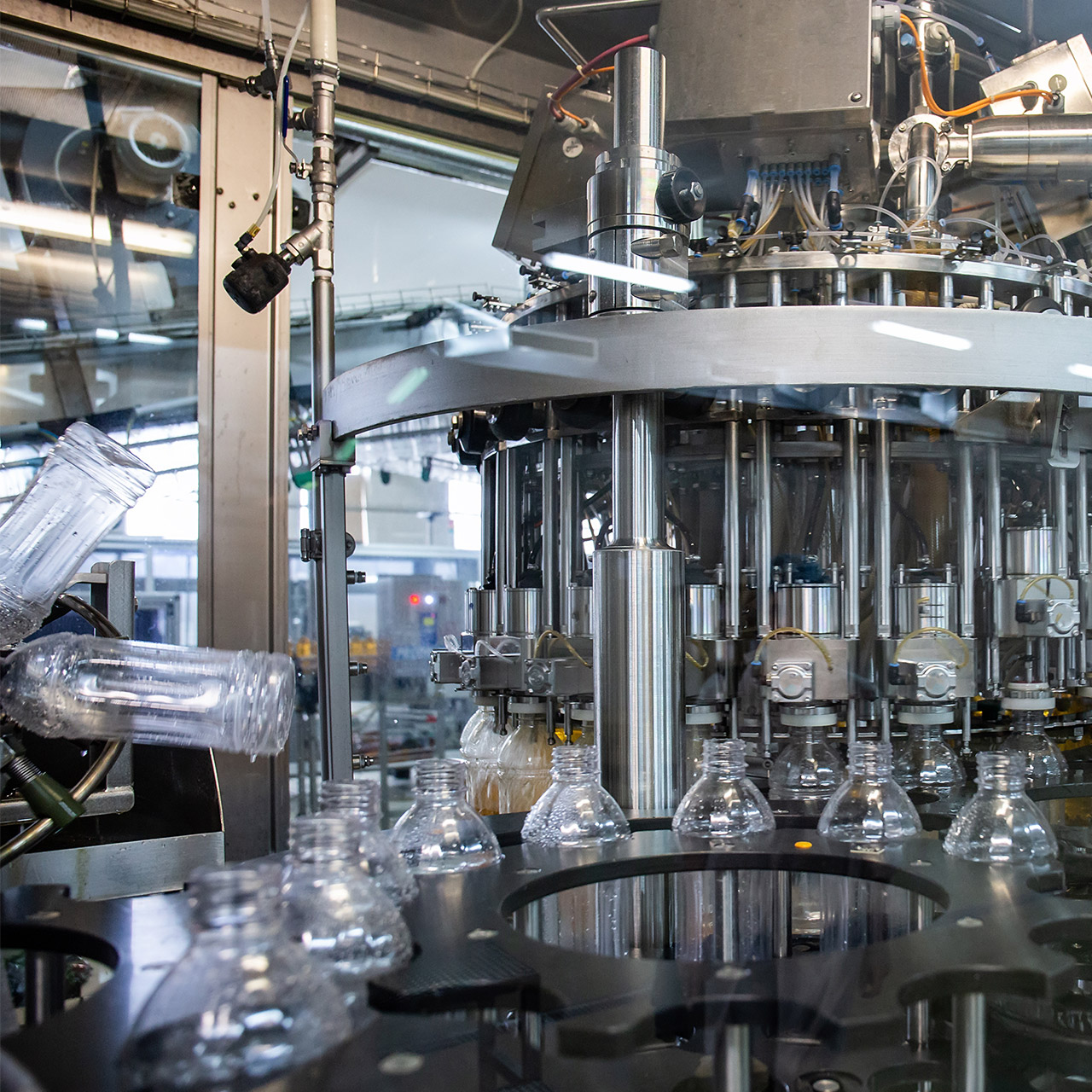

Roller bearings used in the food & beverage industry have specific demands placed upon them

They often must withstand harsh environmental conditions, such as water, steam, or chemicals, as well as lengthy cleaning procedures. For these uses, we at SLF in Fraureuth manufacture bearings made of special materials such as highly corrosion-resistant roller bearings made of Cronidur®.