Bearings for low-noise drives

High quality ball bearings for quieter running

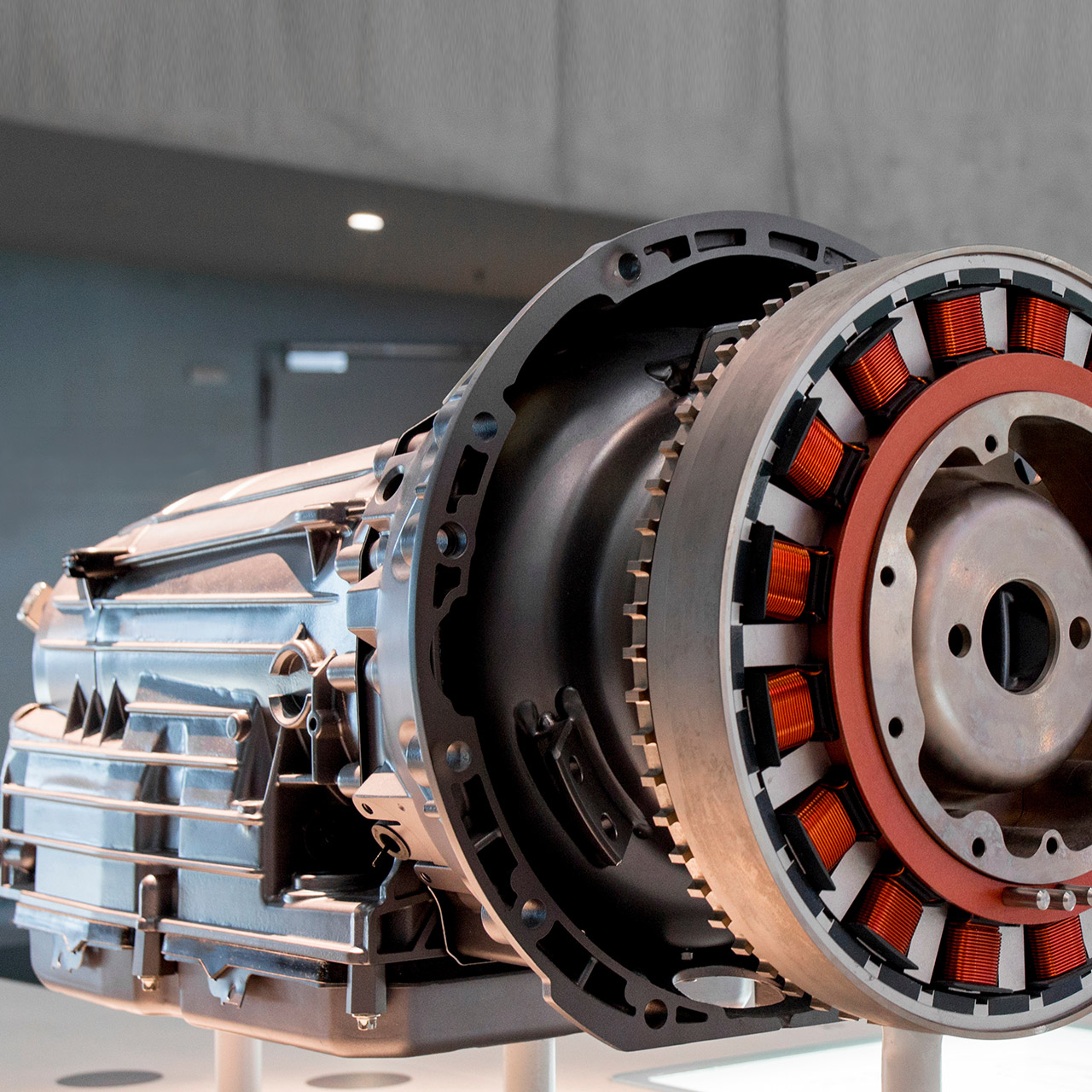

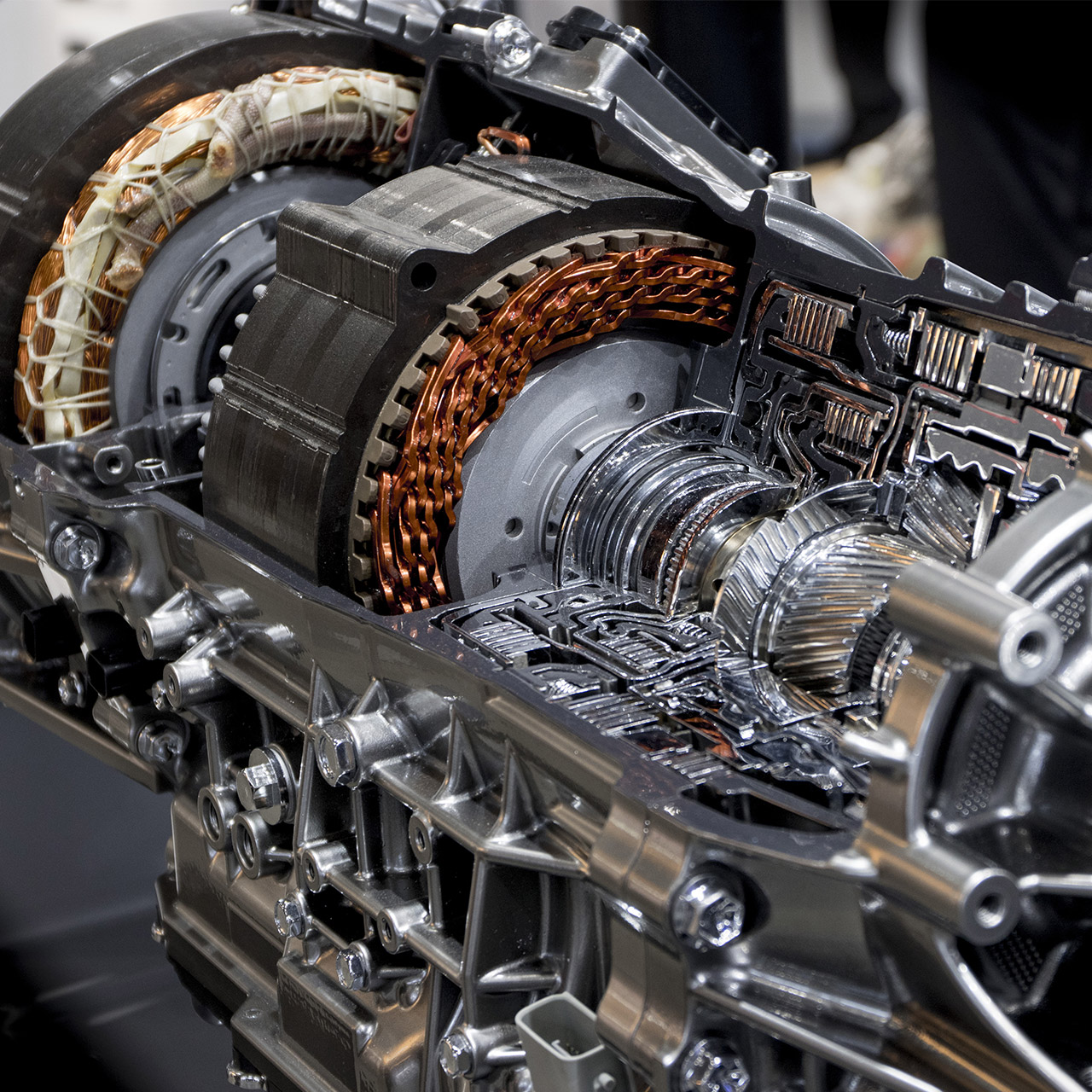

Long-lasting quality, efficiency, and the quietest running possible are the criteria for innovative electric motors. These requirements must also be met by SLF roller bearings, which are not only used in marine, test stand, and vibration motors, but also in compressors and generators. They ensure optimum efficiency with less wear.