Description

Double row full complement cylindrical roller bearings are particularly suitable for bearing positions with high radial loads. These bearings are not only capable of withstanding high radial forces, but also axial loads from one or two directions. In full complement cylindrical roller bearings, the limiting speed is much lower than that of cylindrical roller bearings with cage. Double row full complement cylindrical roller bearings are dismountable, simplifying installation.

Dimension/standards

In double row full complement cylindrical roller bearings, the main dimensions are standardized according to ISO 15 (Radial bearings – boundary dimensions) and DIN 616 (Roller bearings – boundary dimensions).

Tolerances

As the default, we produce double row full complement cylindrical roller bearings at SLF with standard tolerance (PN) according to DIN 620-2 (Roller bearing tolerances – tolerances for radial bearings) and ISO 492 (Radial bearings – dimensions and tolerances). We deliver bearings in other tolerance classes upon request.

Bearing design types

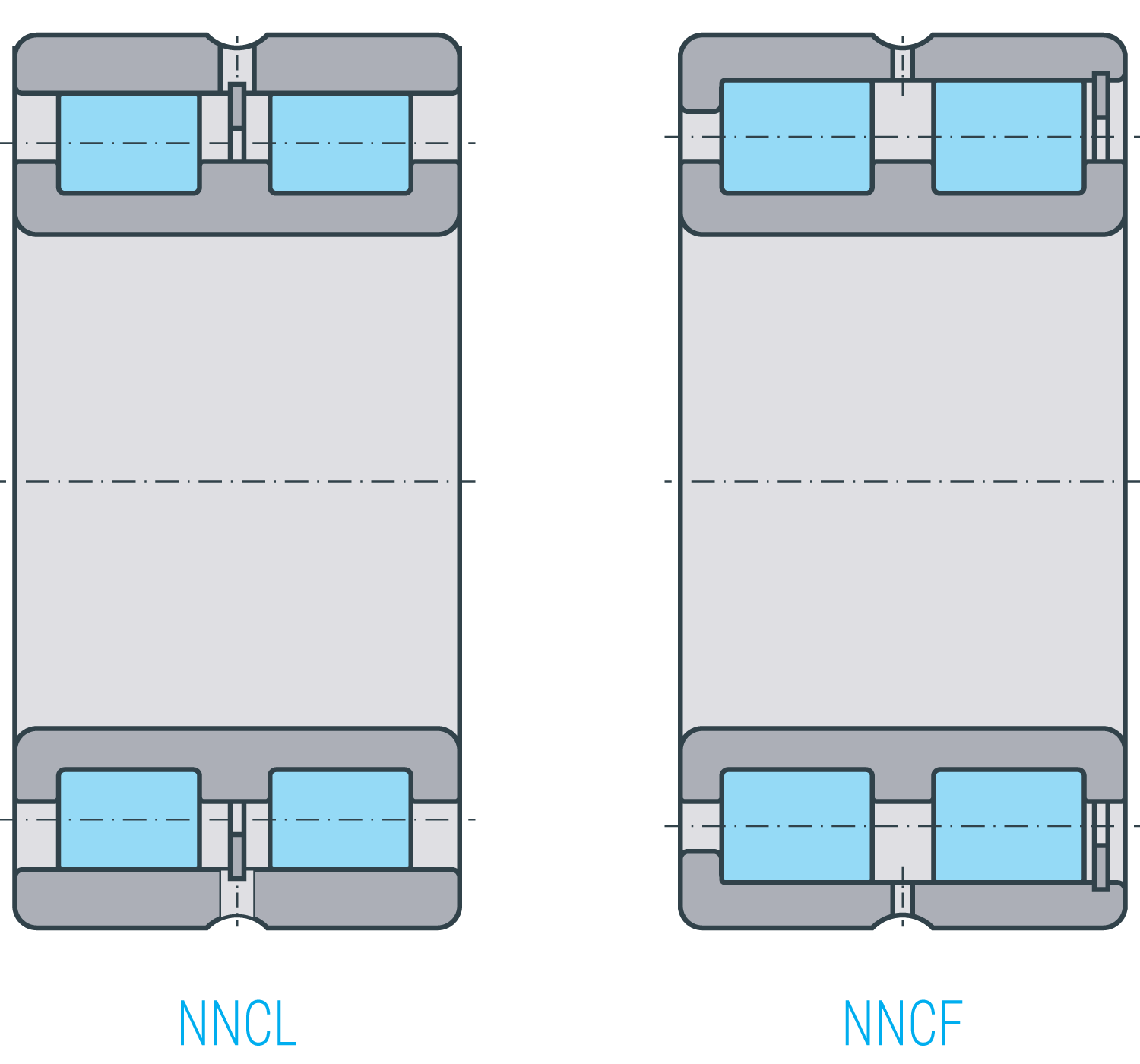

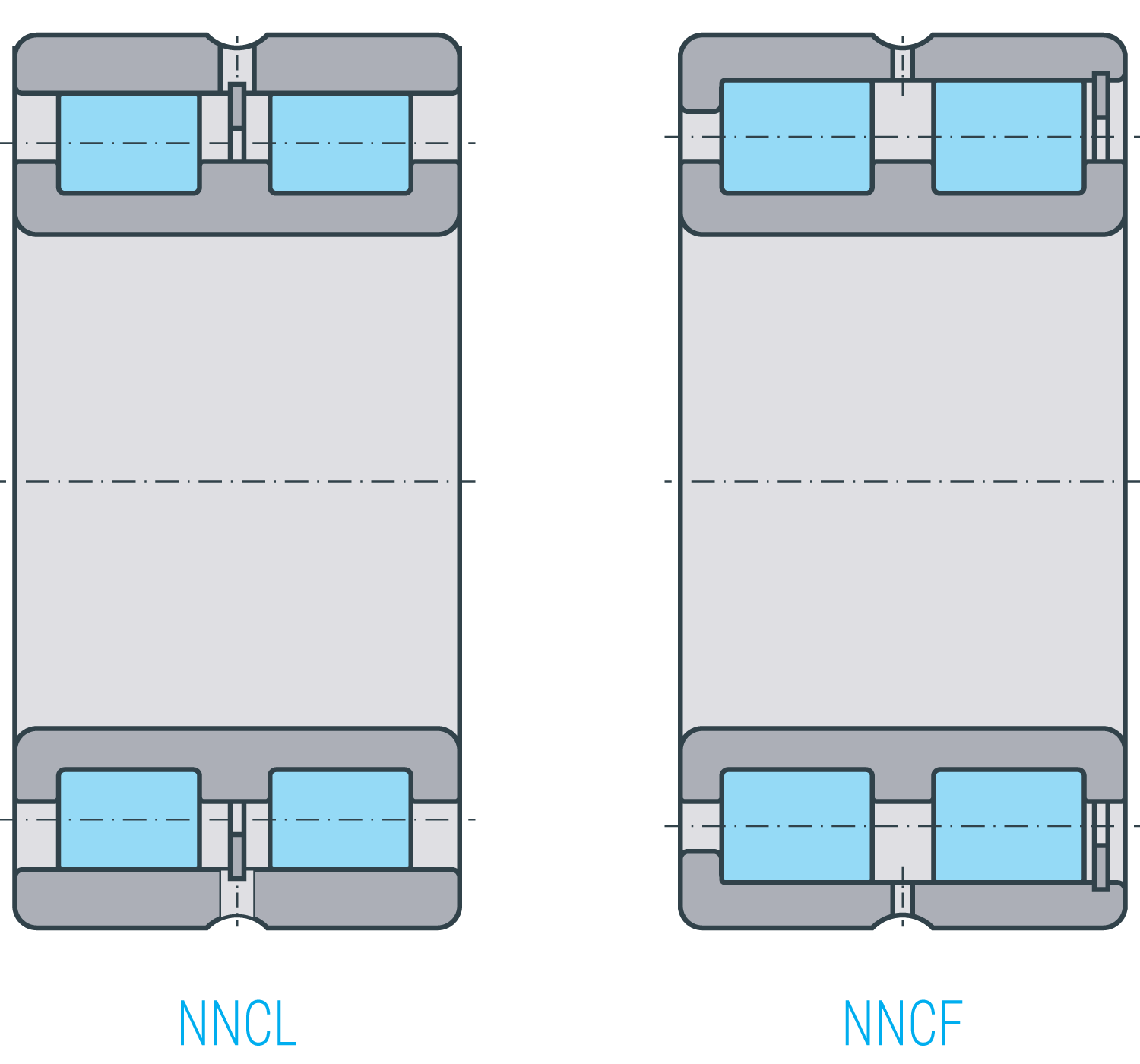

Double row full complement cylindrical roller bearings are produced in the design types NNCL and NNCF, as well as the 48 and 49 series.

Bearings of the NNCF design type are made with three fixed shoulders at the inner ring and one fixed shoulder at the outer ring. These bearings not only withstand extraordinarily high radial forces in one direction, but also axial forces in one direction; another advantage is that they allow slight axial displacements of the shaft against the housing inside the bearing in opposite direction. They can also be used as step bearings.

Bearings of the NNCL design type are made with three fixed shoulders at the inner ring and an outer ring with no shoulder. A retaining ring situated in the outer ring between the roller rows keeps the bearing from collapsing. The retaining ring remains in the bearing even after the bearing is installed and must not be loaded in the axial direction. The bearings permit axial displacements between shaft and housing inside the bearing in both directions.

Clearance

SLF-made cylindrical roller bearings are delivered standard in the clearance class CN according to DIN 620-4 (Roller bearing tolerances – radial clearance) and ISO 5753-1 (Roller bearings – clearance – radial clearance). We can deliver design types in other bearing clearance classes or with special clearances upon request.

Clearance table for cylindrical roller bearings:

Cage

Full complement cylindrical roller bearings have no cage.

Working temperature

SLF double row full complement cylindrical roller bearings with a maximum 120 mm outer diameter are standard stabilized in dimensions by S0, meaning that they are subjected to heat treatment that makes them usable up to a working temperature of 150 °C. At more than 120 mm outer diameter, the cylindrical roller bearings are standard stabilized in dimensions by S1, meaning that they are subjected to heat treatment that makes them usable at working temperatures up to 200 °C. However, as a rule, the maximum working temperature is not limited by the bearing rings’ and balls’ dimensional stability. Frequently the limitation is the lubricant. If you are uncertain or have specific questions regarding the maximal temperatures our bearings withstand, don’t hesitate to contact the SLF team.

Greasing/lubrication & sealing

Double row full complement cylindrical roller bearings are manufactured without seals. Consequently, the bearing location must be sealed around/ on the surrounding components. The sealing must ensure that no moisture and/ or contaminants can enter the bearing and that no lubricant is lost.

The cylindrical roller bearings are delivered ungreased but must be lubricated with oil or grease. Choose the lubricant according to the application.

Dimensioning

Dynamic equivalent load

For floating bearings, the following equation is valid:

For supporting bearings, an axial force Fa may exist in addition to the radial force Fr. The ratio of load must be considered.

| $$P = F_r$$ | for | $$\frac{F_a}{F_r} \leq{e}$$ |

| $$P = 0,92 * F_r + Y * F_a$$ | for | $$\frac{F_a}{F_r} > e$$ |

| P | dynamic equivalent load [kN] |

| Fr | radial dynamic load [kN] |

| Fa | axial dynamic load [kN] |

| e, Y | factors [-] |

Factors e and Y for double row full complement cylindrical roller bearings

| Series | Mathematic factors | |

|---|---|---|

| e | Y | |

| NNCL48, NNCL49, NNCF48, NNCF49 | 0,4 | 0,5 |

Static equivalent load

| P0 | static equivalent load [kN] |

| F0r | maximum radial static load [kN] |

Static load safety factor

For statically loaded cylindrical roller bearings, always inspect static load safety factor S0 in addition to nominal lifetime L (L10h).

| S0 | static load safety factor [-] |

| C0 | static load rating [kN] |

| P0 | static equivalent load [kN] |

Required minimal load

To avoid slippage between elements in contact, the cylindrical roller bearings must be sufficiently loaded. A minimal radial load in the order of magnitude of

has been shown to be necessary.

In most cases, the radial load resulting from the weight of the components run on bearings combined with the external forces is higher alone than the minimal load required. Should this value not be met, contact an SLF application technician.