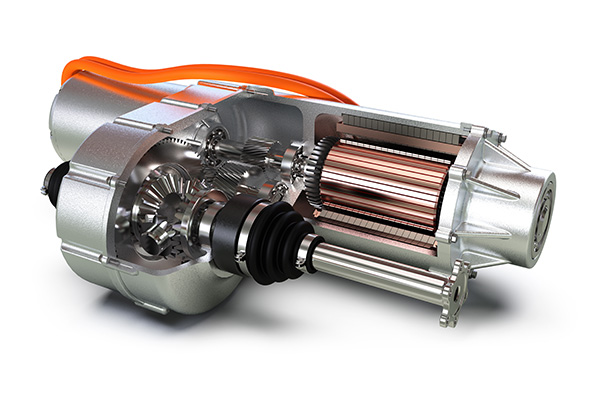

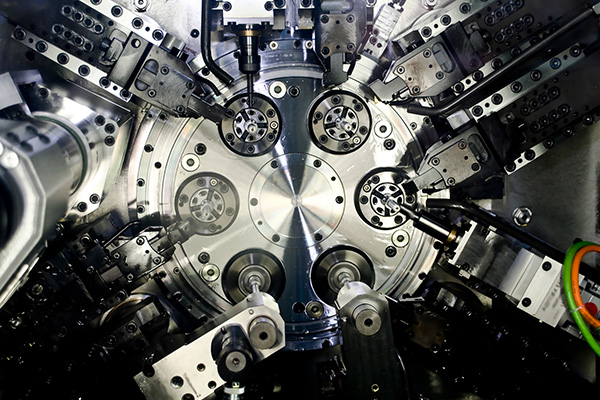

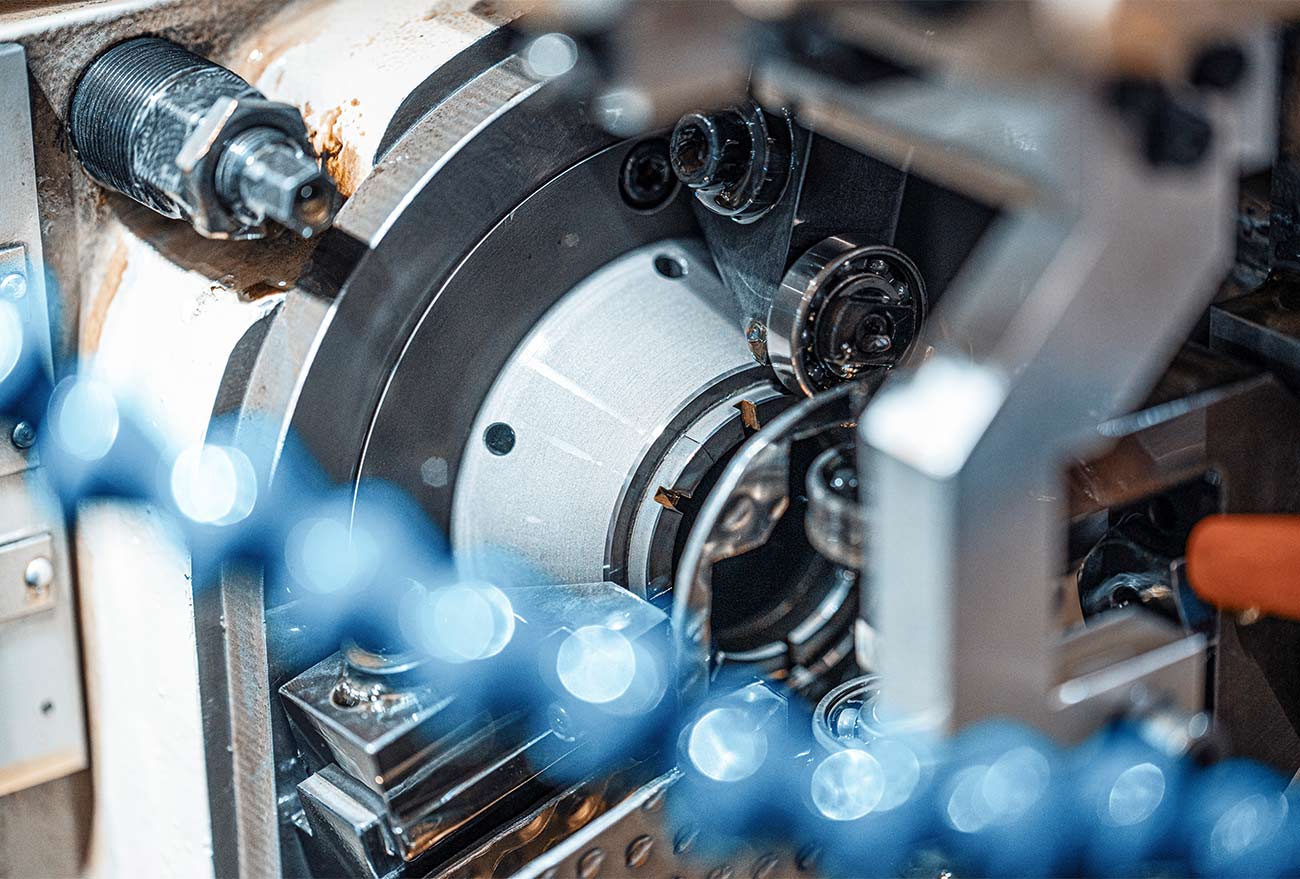

Our range of products comprises roller bearings of various design types, to be used in several industries – from 32 to 1,600 mm outer diameter.

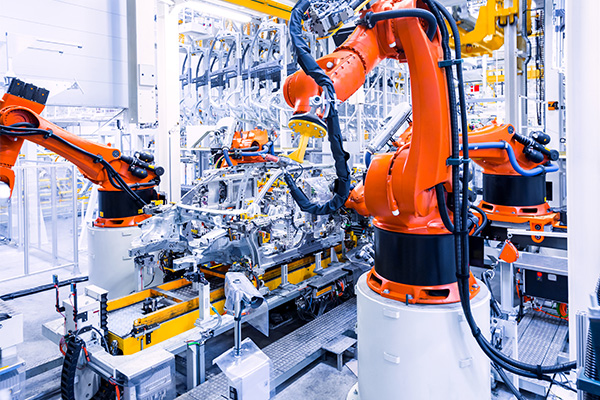

Food and beverage industry

Roller bearings that are used in the food and beverage industry must withstand especially high demands. They are subjected to both harsh environmental impacts and lengthy cleaning procedures. Our range of products reliably and fully meets the requirements of this industry.

Details